|

Optional Arrangements

The Design M FabriPulse is also available in a Bin Vent version and with an integral fan.

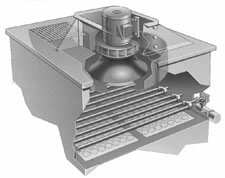

Bin Vent Integral Fan

|

|

Efficiency

The Design M FabriPulse provides 99+% collection efficiency.

Ease of Maintenance

The Design M FabriPulse filter bags are supplied in a unique filter assembly which is accessed from the front of the collector. This allows all of the bags to be installed or removed quickly and efficiently without contaminating the clean side of the dust collector. Filters are easily removed and installed by hand, no special tools are required. The six foot maximum bag length means the Design M FabriPulse can be installed in locations with limited headroom and the bags are accessible from floor level.

Rugged Construction

The Design M FabriPulse is constructed using 12 gauge steel and is true industrial quality. It is structurally reinforced to resist pressures up to -16 inches water column (0.576 psi) and is rated for seismic zone 4. NEMA 4 Controls are standard and heavy duty one inch pulse valves are used to clean the filters with 80 to 100 psig compressed air.

How the Design M FabriPulse Works

Dust laden air enters through the side inlet of the Design M FabriPulse where it is intercepted by an impact baffle which absorbs much of the energy from the airstream. The baffle causes the heavy dust particles to fall directly into the hopper. The remaining dust collects on the outer surfaces of the 2-1/4 in. diameter filter bags. Filtered air flows out of the filter bags into the clean air plenum and is discharged through the outlet. The filter bags are cleaned periodically by a burst of compressed air which is released through valves from a storage reservoir into the clean side of the filter bags. This dislodges the captured dust from the surface of the bag. The dust then falls freely into the hopper below for easy removal. The cleaning sequence is controlled by a solid state control and actuated by either a timer or pressure switch control.

Typical Applications

- Pharmaceutical (Material Handling, Packaging, Bulk Mixing)

- Foundry Shakeout

- Weld Fume

- Laser Cutting

- Metal Grinding

- Woodworking (Furniture Manufacturing, Cabinetry)

- Grit and Sandblasting

- Cereals, Candy, Flour, Food Mixes, and Starches

- Cement, Concrete, Pottery, and Rock Dust

- Paper Dust

Design M FabriPulse - Details

Review Installation & Operation Manual

|