NELIOR Filtration Technology

Nelior® Filtration Technology represents the latest advancement in high-end air filtration. Nelior Filtration Technology is based on a patent-pending membrane air filtration medium that provides unique performance characteristics, unmatched by any other air filtration media currently available on the market. Exclusively developed and marketed by AAF, HEPA and ULPA filters with Nelior Filtration Technology give value-added benefits to applications operating under classified conditions. The result is a more sustainable performance with lower energy consumption and reduced operational risk.

Reduced Operational Risk

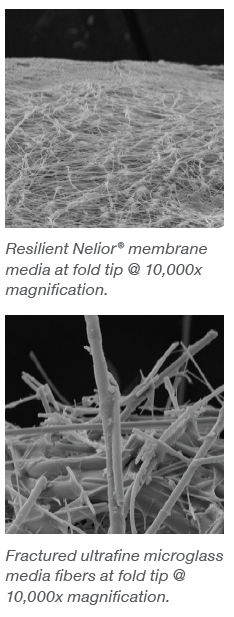

Independent laboratory studies have shown that AAF HEPA & ULPA filters with Nelior membrane media have superior mechanical strength over traditional ultrafine microglass media. The superior mechanical strength is demonstrated by a high tensile strength, burst pressure, and abrasion resistance. Nelior membrane media retains its integrity with a high resistance to any potential damage, for example due to mishaps in handling or installation. In daily practice, this means that the risk of filter media failure is minimized and that fiber shedding, which could cause contamination when entering the airstream, is eliminated.

Chemical Advantages

Negligible Off-gassing

Nelior membrane media has a smaller pore size and fiber diameter than ultrafine microglass. It contains no metals ions, such as boron, sodium, potassium and silicon, that can offgas contaminating sensitive processes. It has near zero offgassing of chemical components resulting in the highest quality clean air available.

High Corrosion Resistance

Nelior membrane media has proven to be resistant in highly corrosive environments including alkaline, acid, and organic substances; common in a variety of manufacturing processes.

Superior Water Resistance

Based on AAF's test lab results, Nelior membrane media provides superior water resistance in comparison with ultrafine microglass and low boron microglass media.

Lower Energy Consumption

HEPA & ULPA filters with Nelior membrane media feature a lower pressure drop than traditional ultrafine microglass media, up to 50% lower depending on the exact conditions. At the same time, the overall filtration efficiency for Nelior membrane media has proven to be higher than for ultrafine microglass media.

The lower pressure drop and improved efficiency are achieved from an evenly distributed layer of fibers with very fine nanometer-scale diameters. Air molecules can efficiently pass through the fibers and airborne particles can be captured more easily. The result: air quality is optimized and energy costs are substantially reduced.

HEPA Filter Integrity Testing

The purpose of installed HEPA & ULPA filter integrity testing, also called in-situ testing, is to confirm a flawless performance during normal operation. With AAF’s new Nelior Filtration Technology, filters can now be scan tested with commercially available photometers at standard PAO concentrations, as well as the low aerosol concentration Discrete Particle Counter (DPC) method.

Availability

Nelior Filtration Technology is available in various styles of filters, including gel seal or gasket seal and plenum style of terminal module style.

|

Nelior® Filtration

Technology Brochure |