Home »

AAF News » Paper Mill Improves Productivity and Saves

September 10, 2012

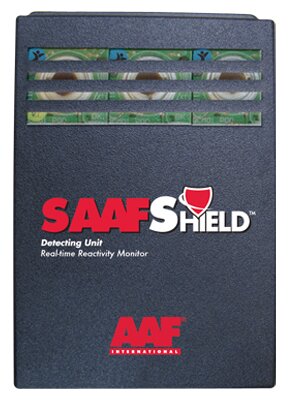

Pulp and Paper Mill Uses SAAFShield®

Technology to Ensure Productivity

The latest case study from AAF International features the SAAFShield® Technology at work in a Northern Michigan Pulp and Paper Mill.

A Michigan pulp and paper mill thought its electronic process control equipment was being protected from failure due to corrosion by using gas-phase filtration products (scrubbers) and services of an AAF competitor. With approximately 25 control rooms housing the electronic equipment to control the mill’s processes, the competitor provided minimal services consisting primarily of the placement of traditional corrosion metal coupons to monitor corrosion and providing replacement gas-phase media for the mills scrubbers.

After experiencing electronic failures in several control rooms, the mill asked AAF International to provide solutions for the facility’s control rooms, equipment, and maintenance practices.

AAF recommended the facility install SAAFShield technology within its control rooms. SAAFShield Reactivity Monitoring allows the user to monitor corrosion activity in real-time or on-demand to determine equipment or electronics vulnerability to environmental corrosion. SAAFShield technology provides the most accurate sensing capability available due to the quartz crystal microbalance (QCM) technology.

You can read the full SAAFShield Case Study or

To learn more about AAF’s SAAFShield® Technology, the new ASHRAE TC 9.9 (RoHS) Standard, or SAAF Side Access Housings contact your local AAF Rep at 888.223.2003